Header: Zoe Mocklar

Sustainability has been part of both formal and informal conversations for decades, and it has led to some real shifts in behaviour from brands and consumers. We still have not reached the goal yet, but it is interesting to see how designers adapt to a new level of carefulness when it comes to production methods and material choices.

The four examples in this article show a few practical routes designers are taking as that carefulness starts to show up in real projects: Closed Loop Footwear uses modularity and a production model based on small workshops and on-demand making; Stella Shoes focuses on vegan-friendly materials and an upper that can be unravelled and redone; Tulip: Designed to Decompose combines reclaimed and recycled materials with biodegradable adhesives intended to let the shoe decompose after use; and Crysm-VX builds its approach around careful material choices, including sustainably sourced fish leather and elements designed to age through wear rather than be replaced. Interestingly, all the designers mentioned here were students at the time of the design, which shows that future generations of designers seem to be more open to the importance of sustainability in footwear design and our day-to-day lives.

The it topic: Sustainability in design

When people talk about sustainability in fashion and footwear design, it usually revolves around two basics: what the product does to the environment and what conditions sit behind its production. On the environmental side, UN Environment Programme figures put the fashion and textiles sector at around 2–8% of global greenhouse gas emissions and also link it to microplastic pollution reaching the ocean. Waste is another hard fact in the background, with the Ellen MacArthur Foundation highlighting that less than 1% of old clothing is recycled into new clothing. On the labour side, large brands were already being challenged in the 1990s over supply chains and sweatshop conditions, and in 2013, the Rana Plaza disaster pushed worker safety back into mainstream discussion.

In footwear design, environmental issues begin during the construction phase. Most shoes are built from a mix of materials and parts (rubber, foams, textiles, plastics, leather, and coatings), and those parts are often stitched and glued together, which makes them hard to separate at the end of the shoe’s life and turn into something useful again. Studies show why manufacturing matters in the conversation: an MIT-led assessment put a typical pair of running shoes at about 30 pounds of CO₂, with much of the footprint coming from making components and assembling the product.

With this in mind, some designers and product teams are rethinking shoemaking in a few practical ways: they are reducing the number of materials so recycling is less complicated, making the main parts easier to separate, switching to more sustainable materials where they can, and pairing products with take-back systems, including subscription-style models and return programmes.

However, while some in the industry are taking steps in the right direction, many others seem to be happily stuck in place. Textile Exchange has reported that global fibre production reached 124 million tonnes in 2023, which matters because footwear sits inside these exact supply chains. Looking ahead, regulation is likely to play a bigger role, at least in Europe, where the European Commission’s textiles strategy is pushing for tougher product requirements so that items last longer and are easier to repair and recycle, alongside tools like a digital product passport and wider producer responsibility.

Examples of sustainable footwear design

Closed Loop Footwear

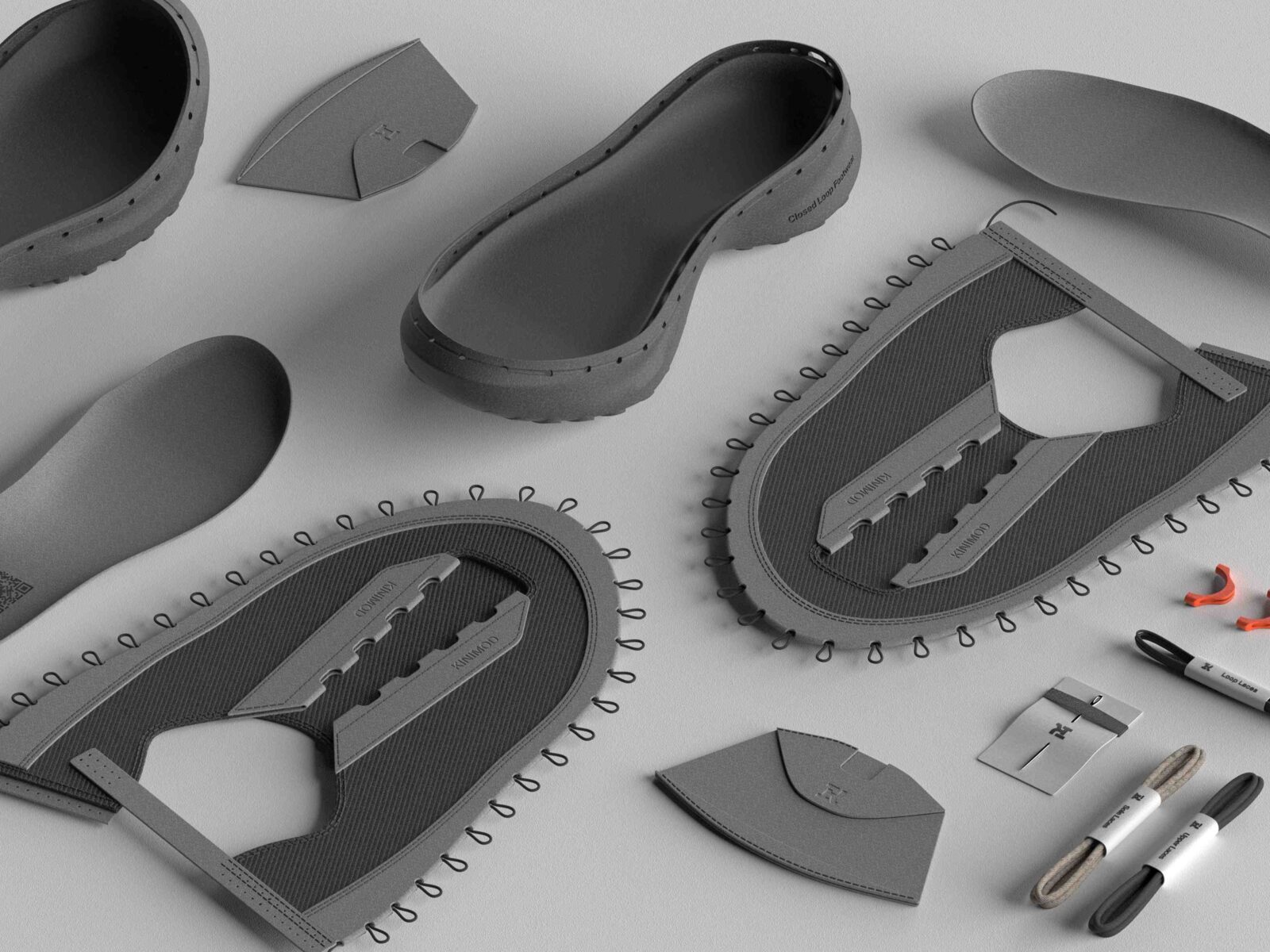

Closed Loop Footwear is a sustainable sneaker designed by Dominik Scherrer, at the time a student from Fh Joanneum Industrial Design, that attempts to give an answer to waste through how a shoe is made, used and dealt with at the end.

This is a modular sneaker designed for a circular economy, as it was built around three practical actions: self-assembly, repair and disassembly. In this concept, those actions are there to extend the product lifecycle and support maximum recyclability, because the shoe is meant to be taken apart rather than treated as trash.

This is only possible due to the sneaker’s production model. The shoe is designed for decentralised production in small workshops, using 3D printing and laser cutting, and it’s dependent on demand rather than stock-based volume. Put simply, pairs are made as needed, which effectively reduces overproduction and waste.

Regarding the materials chosen, they were picked for their recycling and composting characteristics. The designer decided to use banana fibre textile and hemp leather, both compostable and recyclable, alongside TPU, which is recyclable.

Stella Shoes

Stella Shoes is another sustainable design, this time by Adél Horváth, a student from Moholy-Nagy University of Art and Design, which is framed as a material-led response to sustainability. Horváth’s aim was to work exclusively with vegan-friendly materials, a choice that immediately sets the shoe apart from most in the market.

The designer was careful when deciding the construction process, targeting “reuse” as the goal. To achieve this, the upper is crocheted from 100% cotton candlewick cord that can be unravelled once it is worn out or damaged. This is an important technique because it reduces waste, as the shoe can simply be redone as needed. This is a practical example of circularity. The upper is then paired with a wooden heel, keeping the shoe within the project’s focus on natural, vegan-friendly materials.

Tulip: Designed to Decompose

Tulip: Designed to Decompose is a professional heel designed by Zoe Mocklar, a student from the Georgia Institute of Technology, that was born from careful consideration of materials and what happens to a shoe when it reaches the end of its life.

The sole is crafted from tulip poplar offcuts, and the upper fabric is made from recycled wool. Inside, the designer added a cotton lining, a material also used in the stitching. These materials show that the heels are built from recycled and reclaimed materials, reducing waste.

Another important element of this design is planned decomposition, as the designers used biodegradable adhesives that allow the shoe to completely decompose after its lifecycle comes to an end.

Crysm-VX

Crysm-VX is a boot designed by Sophia Denison and Drew Kibler, both students from the Savannah College of Art and Design. Its design differs from mainstream shoemaking because of the way it views the boot itself: it is an exoskeleton reimagined as an“organic, performance-enhancing symbiosis between the body and nature’s protective systems“.

The boot is hand-woven from copper and cotton, a material choice meant to help with thermoregulation, offer antimicrobial aid and provide energetic conductivity. The shoe was also designed to change with use, developing a patina that makes each pair unique. Furthermore, the designers used sustainably sourced fish leathers for grip, breathability and abrasion resistance.