Header: YUMA / Emily Stroph & Valérie Vendramin

Since the development of 3D printing technology in the early 2000s, the concept has continued to grow, gradually reshaping the shoemaking industry. Initially used as a tool for creating complex, artistic, one-of-a-kind pieces, the technology has steadily moved into the mainstream. Today, even major footwear companies incorporate 3D printing into their production processes. Adidas, Nike, New Balance, Dior, and Reebok are just some of the global brands exploring the possibilities offered by 3D printing. As the use of 3D printing continues to grow, we ask ourselves: what are the benefits the technology can bring to its wearers and the industry itself?

Custom-made shoes

To start, the ability to adjust footwear to its user is a game-changer for the shoemaking industry. A simple foot scan will be enough for a company to get the measurements and create a tailor-made model for your foot. The technique can be particularly useful for people suffering from foot deformities (flat feet, bunions). Until now, buying specially designed orthopaedic shoes had required a lot of money and several visits to the podiatrist, but the new 3D-printed shoes can reduce the time and costs of the process. Even perfectly healthy people can benefit from custom-made footwear that will make their feet lighter and help them avoid foot pain, blisters, and calluses.

Emily Stroph; Valérie Vendramin

Decentralisation of the footwear industry

It is not easy to make a name for yourself in the competitive footwear industry. But with a 3D printer, your chances improve. 3D-printed footwear enables faster creation of shoes based on someone’s sketches without (or with minimal) cutting, stitching, or technical assembly. You would need a whole set of expensive tools for precision cutting and footwear manufacturing, alongside expensive pressing, stitching and sewing machines, to get your company off the ground. In the past, opening your own company would require a lot of money, but now you can do it all almost single-handedly with a computer, 3D printer, and selected materials.

Reducing environmental impact

The world of fashion is notorious for the imprint it leaves on the environment. Fast fashion relies on mass production of low-quality products to reduce the prices of footwear. As a result, around 23.9 billion pairs of shoes are manufactured globally, resulting in large carbon emissions, energy use, and tons of waste. 3D printing can save the environment by reducing the energy needed for manufacturing.

The additive manufacturing, typical of 3D printing, which includes printing materials layer by layer to form a desired shape, has a lower carbon footprint than traditional manufacturing processes. By making footwear from discarded or recyclable materials, such as ZellerFOAM, the technology reduces waste and allows for the reuse of materials. The 3D printing process uses only the needed material without any leftovers, which reduces waste.

Artistry and design

Finally, the 3D printers open up a whole new world of creativity for footwear designers. The printing process allows for the creation of shapes and patterns impossible to achieve by any other means. An endless pool of posibilities allow the designers to go wild in their work, creating never-before-seen, fashion-forward choices.

Ötzi Frozen Fritz – Endless Shoes

The 3D-printed shoes designed by Shelly and Elon Satat-Kombor with Shelly Boneh navigate the boundary between contemporary design and traditional craftsmanship. As its name suggests, Ötzi Frozen Fritz – Endless Shoes draws inspiration from the 5,000-year-old mummy discovered in 1991. The mummy was named Ötzi, after the homonymous mountains on the Austrian-Italian border, although it is frequently referred to as Frozen Fritz in some parts of the globe. The alpine cold preserved the body well, but more surprisingly, it did wonders in preserving the Iceman’s shoes. Made of three kinds of leather: brow bear skin for the bottom, cowhide on the straps, and roe deer skin for the upper and back part of the shoes, these shoes were made with a glueless, nailless technique of weaving the shoes together. Layers of grass held together by a lime tree bast fibre net were used for isolation. Although assembled by folding by hand, the contemporary rendition of the world’s oldest shoes employs modern techniques as well.

By combining 3D-printed components with classic folding techniques and digital planning, the project reflects on the current ecological crisis, positioning the shoes as instruments of resilience and reflection. Referencing ancient survival tools, the design leaves both physical and conceptual traces while questioning prevailing norms of production, consumption, and material use, practices that often carry major environmental consequences. Handmade from discarded materials, Otzi Frozen Fritz – Endless Shoes further highlight the project’s environmental focus. Endless Shoes received a Special Award in the 3D Print Footwear category at the Global Footwear Awards.

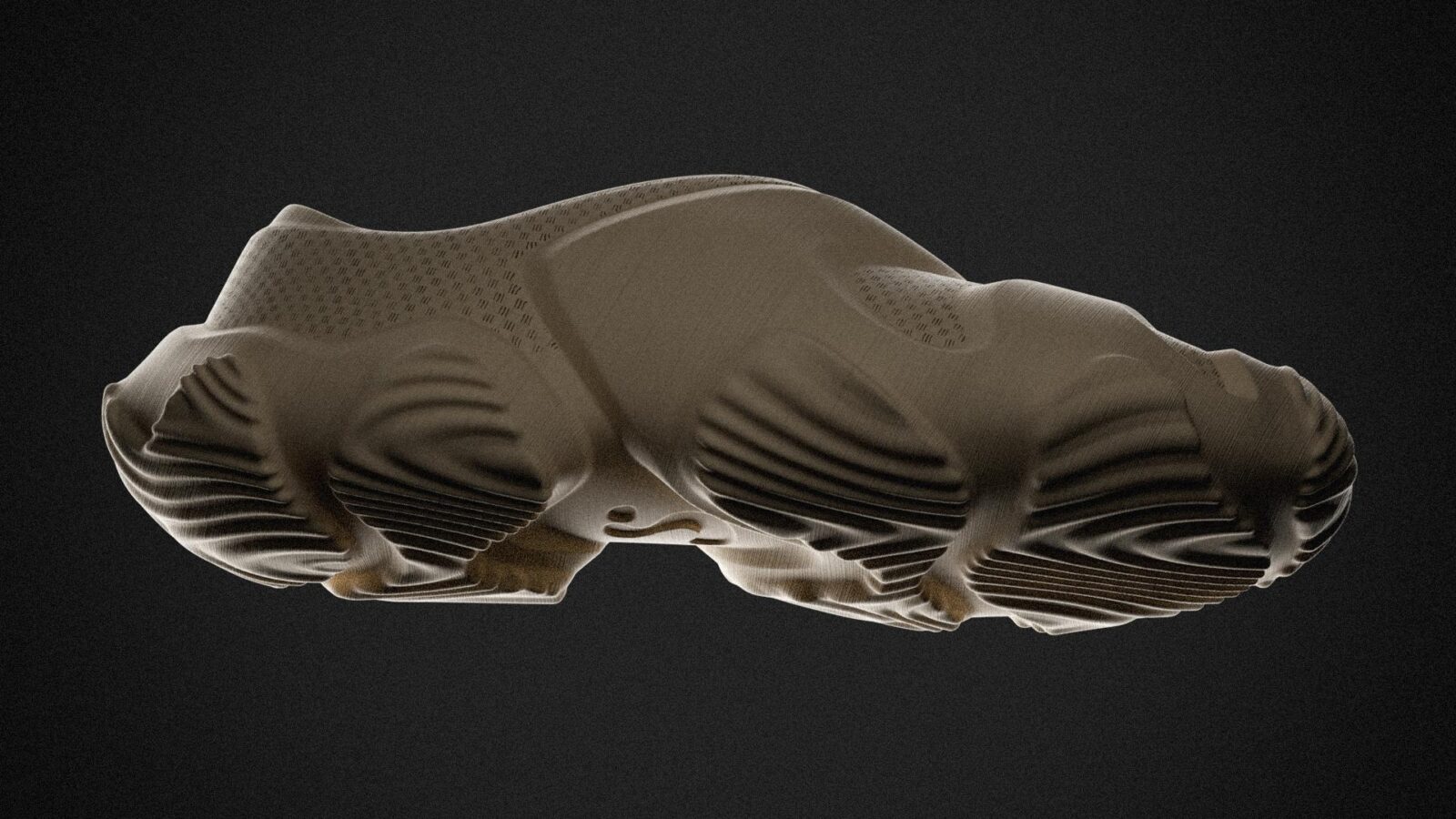

YUMA

YUMA shoes represent a design project aimed at exploring the sculptural potential of 3D printing in the world of fashion. The comfortable YUMA shoes are made from recyclable material called zellerFOAM, a specially developed TPU – Thermoplastic Polyurethane known for flexibility and resistance to impact, UV, and chemicals. Lead designer Victor Stroph was inspired by the desert landscapes and ancient symbolism described in the popular Sci-fi novel Dune by Frank Herbert. As a result, the design echoes the fluid motions of sand dunes.

By wrapping itself around the human form in almost a ritualistic manner, the sneakers balance comfort, innovation, and form. YUMAs are made on demand by Zellerfeld. A US company known for its custom-made 3D printed shoes has already collaborated with NIKE on the creation of a new AIR MAX 95000 model. A futuristic reimagining of NIKE’s iconic Air Max 95000 transferred the attitude and aesthetics of the original into the new 3D-printed version. Zellerfeld, a company founded in 2020, allows for purchases in standard sizes or custom-made to fit the dimensions of your foot (if you send them a foot scan for reference). At the Global Footwear Awards, the design for YUMA has won the 3D Print Footwear award and was named an overall winner in Special Awards.

Changing the footware industry one shoe at a time

Once handmade from hide and grass, shoes have come a long way from their prehistoric roots to modern 3D-printed designs. New technological developments can permanently alter the way we think about footwear by enabling custom-made, cost-effective, and sustainable pairs that help both wearers and the planet thrive.