Header: Courtesy of Xiaomi Corporation

Xiaomi has just introduced the YU7, its first SUV and second electric vehicle model, built on an entirely new platform rather than being a simple adaptation of the SU7 sedan. While the two vehicles share a common look, the YU7 has been developed with its own proportions, technical features, and spatial layout that reflect what a mid-to-large SUV should be like. Positioned as part of Xiaomi’s broader strategy to enter China’s high-performance EV segment—and directly challenge established players such as Tesla—the YU7 expands the brand’s ambitions beyond compact, everyday sedans into a more competitive, full-scale offering.

Instead of trying to replicate the visual impact of its first model, the YU7 takes it a bit further, adjusting height, stance, and detailing to match the SUV typology. At nearly five metres in length with a three-metre wheelbase, the vehicle’s long, low look was made possible by careful adjustment of ratios — between wheels and body, width and height, as well as between individual body sections such as hood and cabin. While these may seem like small details, they shape how the vehicle sits on the road and influence everything from aerodynamics to interior volume.

Everything about the visual design

At first glance, the YU7 has the signature lines seen on the SU7, including the low nose, strong shoulders, and continuous side profile, but the overall look has been adapted to create a more upright silhouette. One of the key structural elements is the clamshell hood, the largest in any current mass-produced vehicle, mind you, which is connected to the front through an aluminium unibody panel. This piece covers over three square meters and houses a 141-litre front trunk, designed to open in multiple modes depending on user settings.

Other elements have been reworked to match the SUV scale. The headlights, for example, use the same “waterdrop” theme from the SU7 but are now hollowed at the top to create air channels that guide flow through the front fenders. These openings are both visually interesting and functional, as they hold vents that help reduce turbulence while also giving the vehicle a more defined front. The taillights follow a similar logic, with reshaped clusters that slope slightly downward to reinforce the wider, more planted rear view, using a deep-red lighting tone typically found in higher-end vehicles to improve visibility in low light.

On the side, the vehicle was given retractable door handles that stay connected to the body until the user approaches, at which point they extend automatically. The system works while stationary or in motion and includes internal lighting to help guide access at night. This detail, while small, fits into the design’s care for smooth body surfaces and controlled airflow, both of which are central to how the YU7 reduces drag and extends range.

Three paint finishes were created for the launch, each using a multi-layer application process that alters how the surface reacts under different light conditions. The most complex of these, Emerald Green, uses aluminium flakes embedded in a yellow-green metallic base, followed by a translucent pearl layer to produce subtle shifts in depth and brightness. Titanium Silver uses larger flake particles to create stronger contrast between shaded and reflective areas, while Lava Orange, which was introduced on the SU7, is a more saturated and sporty tone applied on a double-coat system.

Inside, the YU7 applies the same design focus to materials, layout, and spatial organisation. The front dashboard is lowered and layered to avoid blocking the driver’s view and to reduce the bulky appearance often found in SUV interiors. Most areas are soft to the touch, and seating is finished in Nappa leather with a textured grain. The colour palette includes light and dark combinations, with Pine Grey, Coral Orange, and Twilight Blue offered as options.

Regarding the seating itself, the two front seats are built around a “zero gravity” reclining structure, which spreads body pressure more evenly, especially on long drives, and includes heating, ventilation, and ten-point massage settings. The rear seats, on the other hand, are electrically adjustable and can tilt between upright and lounge positions.

Let’s talk about the engineering

The Xiaomi YU7 was developed with a strong focus on how the car moves through air, distributes weight, and delivers energy, and while these themes are common to most electric vehicles, here they’ve been approached in a way that favours small, cumulative changes over dramatic solutions. The result is a drag coefficient of 0.245, a figure that places this car among the most aerodynamically efficient vehicles in its class, something achieved not through extreme shaping but through dozens of design decisions that adjust how the car behaves at speed.

Many of these changes are built into areas that aren’t immediately noticeable: ten pass-through air channels and nineteen vents are positioned to manage airflow in and around the body, helping to reduce resistance and direct cooling where it’s needed; a hollow rear spoiler, reshaped through multiple design cycles, adds downforce while minimising drag; and at the front, an active grille system uses one hundred small shutters that open and close automatically depending on speed and temperature. Even the clamshell hood, which at first seems purely aesthetic, contributes to airflow by removing panel gaps where air separation might occur.

The suspension setup follows a similar logic, where the emphasis is less on a single system and more on how its parts behave together. At the front, a double-wishbone layout provides stability during cornering, while at the rear, a five-link suspension helps absorb road changes without letting the cabin vibrate. These systems were paired with dual-chamber air springs that can raise or lower the vehicle depending on conditions or driving mode, offering up to 75 millimetres of travel. Through continuous damping control, firmness is adjusted while the car is on the road, allowing it to stay composed on uneven terrain without sacrificing responsiveness on smoother roads.

Braking performance has also been tuned, as the designers used a four-piston calliper system that brings the car to a stop from 100 km/h in just under 34 meters — a figure more typical of sports sedans than large SUVs. The YU7’s turning radius, at 5.7 metres, makes it the perfect choice for tighter urban areas, something that sounds like a dream for any SUV owner.

Power is delivered through Xiaomi’s HyperEngine V6s Plus, which uses a segmented magnetic steel design to reduce internal resistance and improve efficiency during high-speed operation. Instead of relying on a single magnetic section, the rotor is divided into smaller pieces, which helps lower energy loss and improves smoothness during acceleration. In the dual-motor version, this setup produces a peak output of 690 PS, reaching 100 km/h in 3.23 seconds, while maintaining a top speed of 253 km/h.

All versions of the YU7 use an 800V battery platform, which supports high-power fast charging without excess heat build-up. The Standard and Pro versions are equipped with a 96.3 kWh battery, while the Max version increases capacity slightly to 101.7 kWh. Despite the different configurations, range performance is consistent throughout the series, with the base model reaching 835 km under CLTC testing, while the dual-motor Pro and Max versions achieve 760 and 770 km, respectively.

What about technology?

The cabin of the Xiaomi YU7 was especially shaped by the way information is displayed, shared, and adjusted during travel. At the center, designers added a new kind of screen experience, where the traditional dashboard layout is replaced by an extended projection that uses a combination of mini LED panels that wrap into the driver’s line of sight.

What sets this system apart is how it changes based on what the car is doing and who is using it. Speed and navigation data are always in sight, while media or environment controls can shift toward the passenger side when needed. During turns or lane changes, the projections are adjusted to guide the driver through the motion, and when driver assistance features are activated, the layout transitions to a simplified representation of nearby vehicles and road conditions. In addition to the windscreen projection, the YU7 has a separate control panel that allows passengers to manage navigation, media, or comfort settings directly, without needing to reach for the main screen, be it in the front or rear.

None of this would have been possible without a good electrical engineering, which comes down to an innovative shared processing unit. This component, referred to by Xiaomi as a “four-in-one” controller, combines vehicle control, infotainment, connectivity, and driver assistance functions into a single spot. By doing this, the overall system becomes lighter and more compact, but also more responsive, as communication between different parts of the vehicle happens without delay or duplication. From the user’s perspective, this makes small tasks like switching between functions or installing updates noticeably quicker.

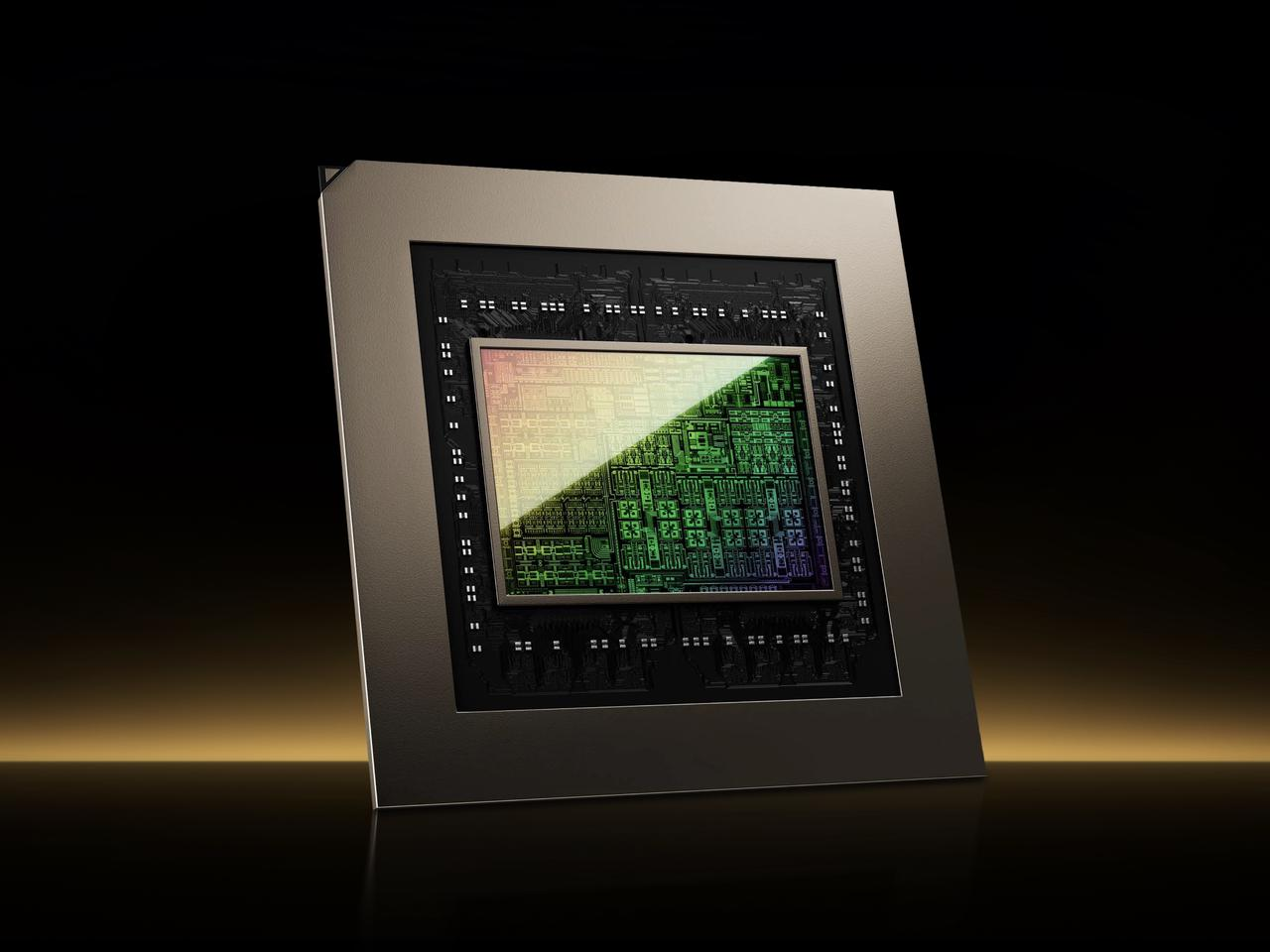

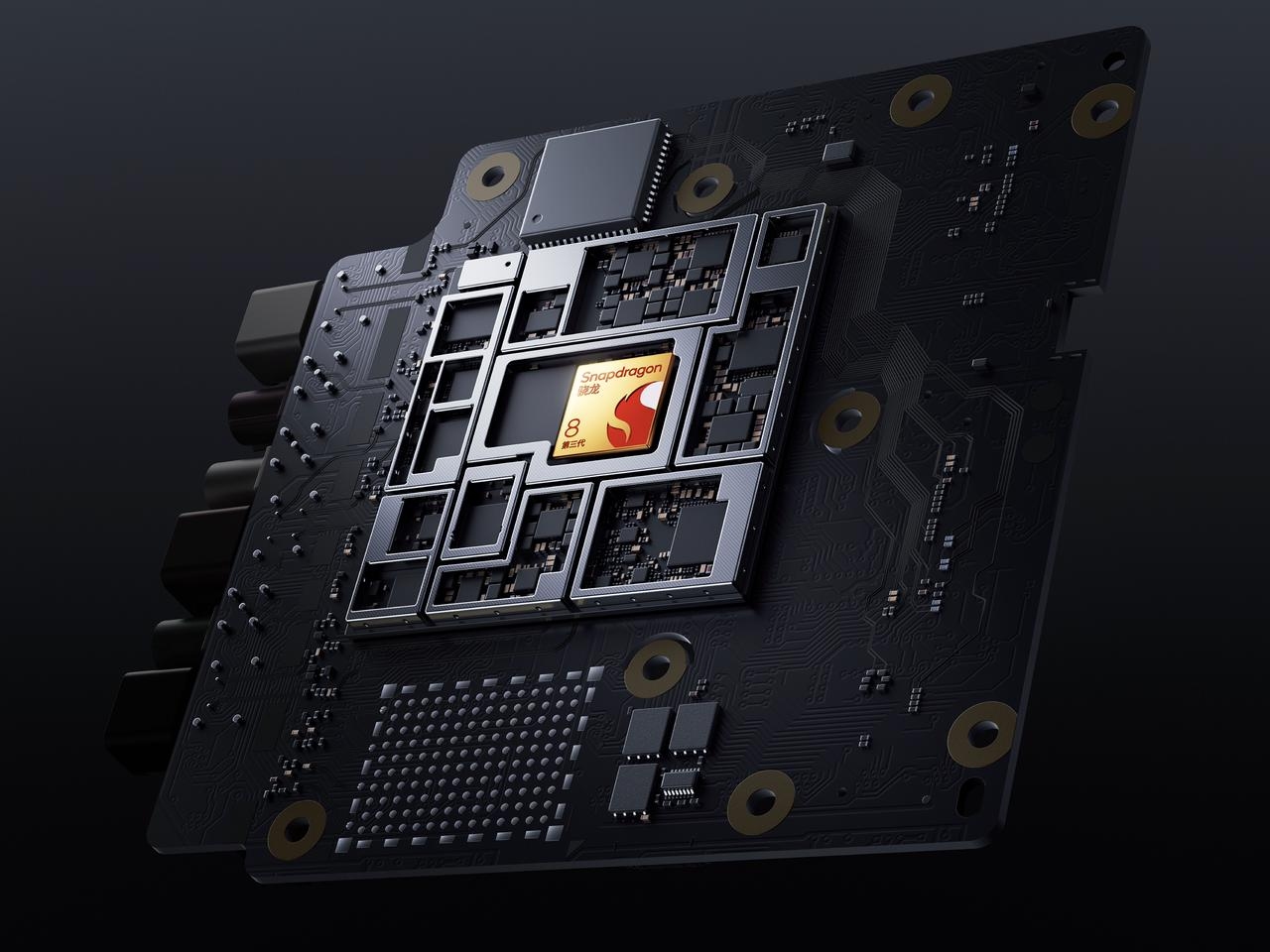

The user interface inside of the cabin is handled by a Snapdragon 8 Gen 3 chip, which offers fast processing while keeping power use efficient. In the assisted driving system, a separate platform is used: NVIDIA’s DRIVE AGX Thor, which supports real-time image processing, mapping, and predictive modelling. This allows the car to respond to changing road conditions by drawing from data collected by multiple sources — not just cameras or radar, but a combination of eleven high-definition visual sensors, twelve ultrasonic units, one LiDAR system, and a 4D millimetre-wave radar that can read movement and distance more accurately than earlier-generation versions. The connectivity was also updated: Wi-Fi 7, dual 5G networks, and ultra-wideband keyless entry allow the car to link with mobile devices or home networks, while Bluetooth continues to be a given.

Lastly, safety

In the structure of the Xiaomi YU7, safety systems weren’t treated as a separate set of features but as part of the layout and material choices. Every element that supports the body — from the frame to the underbody crossbeams — was shaped to manage how energy moves through the structure during impact, keeping the cabin stable and reducing stress on critical components like the battery pack and suspension anchors.

At the front, the frame includes a crumple zone that extends over 650 millimetres, giving the car more distance to slow impact forces before they reach the passenger area. At the rear, the vehicle was given a three-part die-cast floor first used in the SU7, which improves rigidity and gives the structure a consistent base, especially in cases of rear-end collisions. Across the underbody, a crossbeam made from high-strength steel was added to protect the battery casing from damage caused by debris or sudden contact with uneven road surfaces.

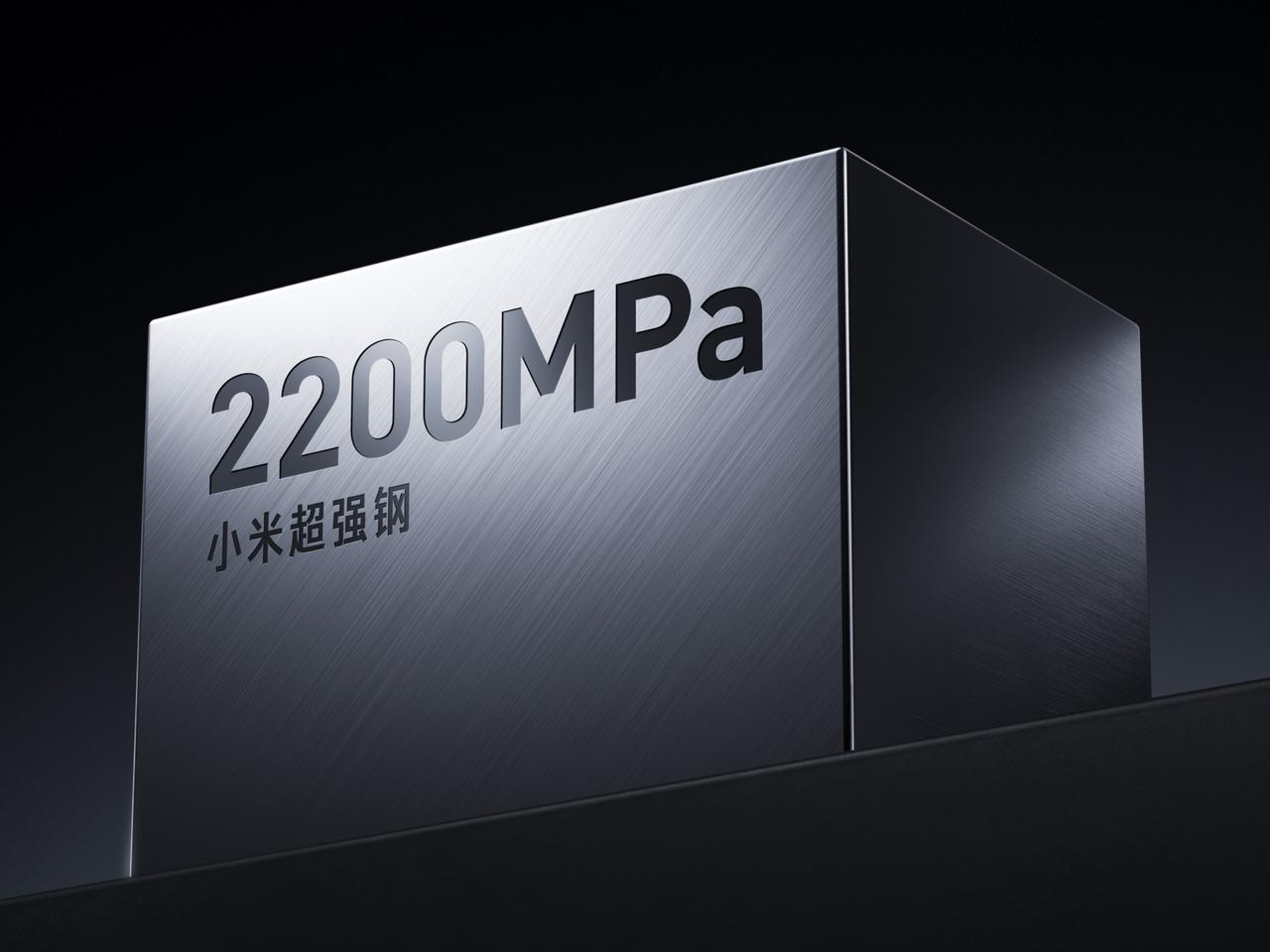

One of the more significant updates in the YU7 is the introduction of a new ultra-high-strength steel developed in collaboration with material researchers and manufacturing partners. With a tensile strength of 2200 MPa, an increase from the 1500 MPa steak previously used, this new material can absorb more energy, allowing key parts of the vehicle — such as the A- and B-pillars — to maintain their shape in impact situations. The steel was also added to the inside of all doors, forming internal reinforcements that help prevent dire situations.

Beneath the car, a multilayer coating (already mentioned) provides protection for the battery compartment, using a material more commonly found in industrial and military applications. It resists tearing and puncture more effectively than standard PVC coatings and is designed to remain intact in cases of scraping or contact with sharp surfaces, reducing the risk of damage to the battery cells from below.

The stiffness of the structure was achieved through the combined use of aluminium and high-strength steel, which together account for more than 90 per cent of the body’s total material composition. The resulting torsional rigidity — measured at over 47,000 newton-meters per degree — helps maintain cabin integrity not only during impact but also during normal driving, where the stiffness contributes to steering precision and chassis stability.

To ensure these choices truly make a difference, the YU7’s safety systems were tested across more than fifty crash and deformation scenarios, covering both regulatory and internal procedures. These include front, side, offset, and rollover conditions, along with tests that simulate high-speed impacts and under-ride events, in line with standards such as C-NCAP and C-IASI.