Header: Courtesy of Volvo Car Corporation

Volvo Cars has introduced a new version of the safety belt, ensuring that it can now respond more precisely to real-world crash conditions. The multi-adaptive safety belt will first appear in the fully electric Volvo EX60, scheduled for release in 2026, and is set to woo the security sphere of the automotive world.

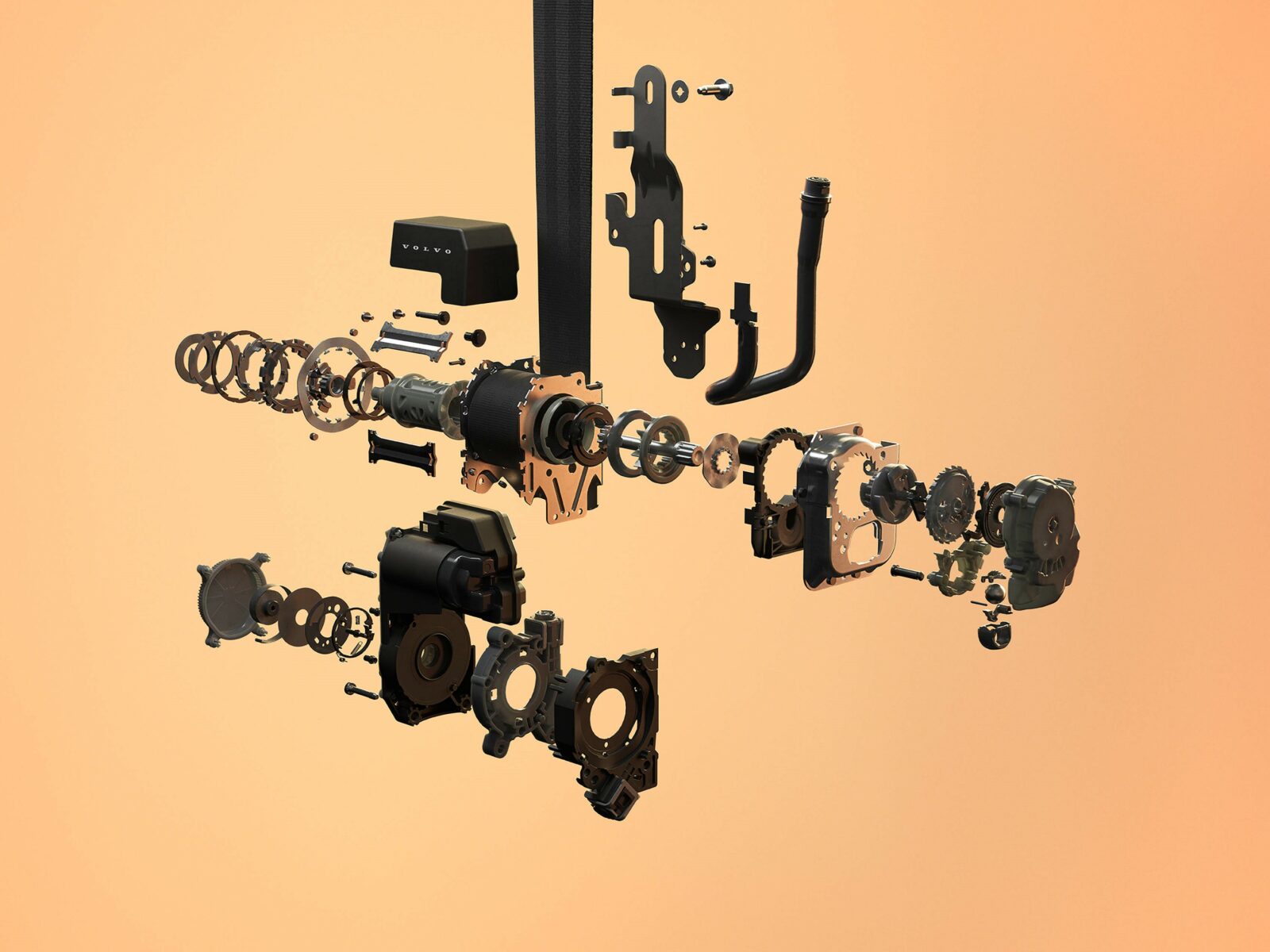

Drawing on data from both interior and exterior sensors, the system adjusts how the belt functions in response to the situation and to the physical characteristics of the occupant, such as height, weight, body shape, and seat position. In the event of a crash, the system adapts itself following a broad range of load-limiting settings, increasing the belt’s ability to manage force across different occupant types and collision scenarios.

For example, a higher belt load may be applied to a larger occupant during a severe crash to reduce the risk of head injury, whereas a lower load may be used for a smaller occupant in a less severe collision to lower the risk of rib injury. The new safety belt has three to eleven load-limiting profiles, and as the system is updated over time via software, the calibration can be refined further.

“This marks a major upgrade to the modern three-point safety belt, a Volvo invention introduced in 1959, estimated to have saved over a million lives.”

Åsa Haglund, head of Volvo Cars Safety Centre

Use of real-world data

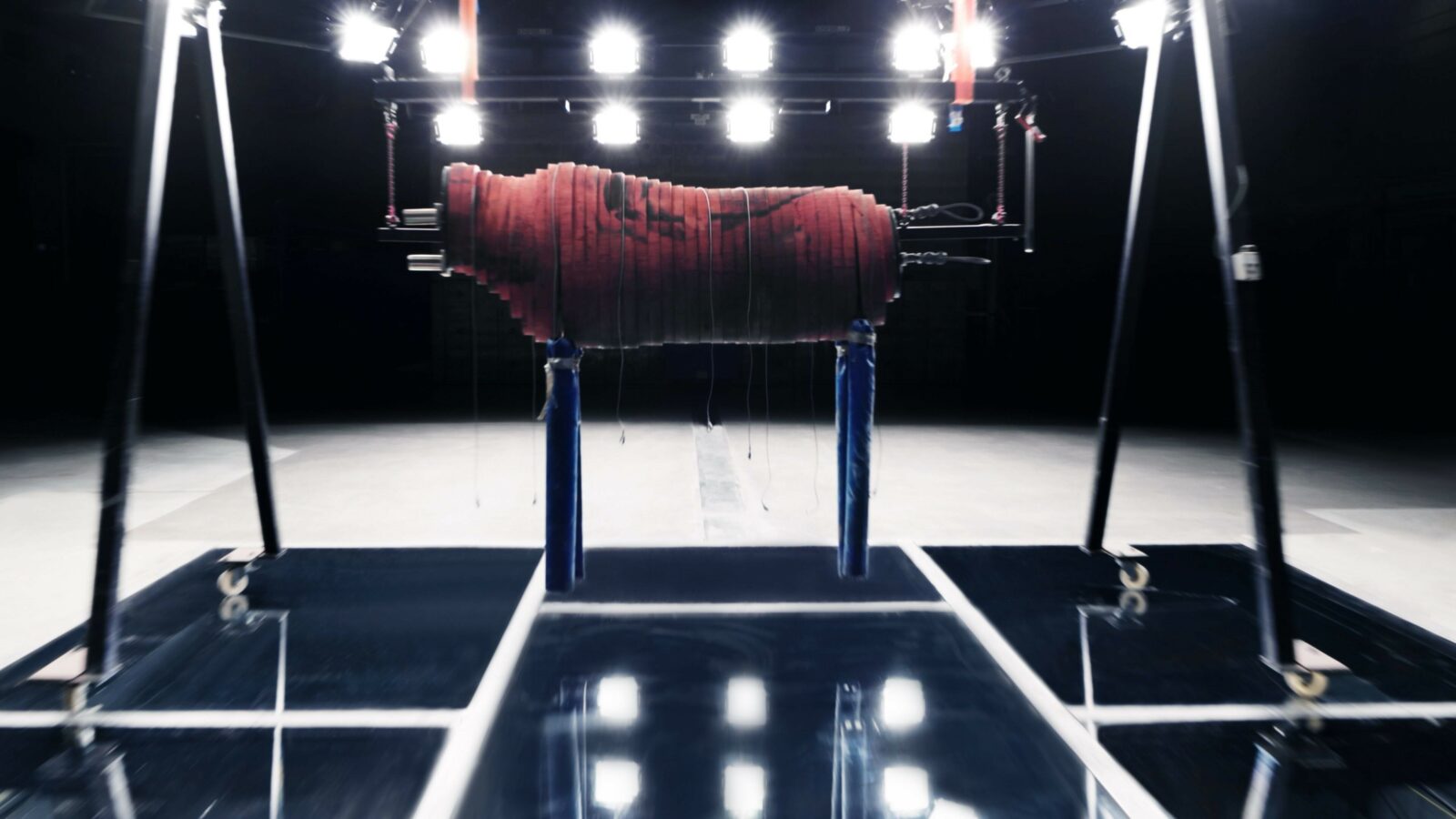

The development of the multi-adaptive safety belt comes after decades of internal crash research and a proprietary database of more than 80,000 real-world occupants. This study has allowed Volvo Cars to account for a wider range of crash scenarios and occupant profiles than those typically included in regulatory testing.

This is part of the company’s ongoing work to adapt restraint systems for varied real-life conditions, hoping to move beyond the fixed parameters used in traditional systems. The new belt works in coordination with sensors located throughout the vehicle, including those monitoring external conditions, cabin dynamics, and the moment of impact. This system processes the data in real time to determine the appropriate restraint profile, based on crash direction, vehicle speed, occupant posture, and other variables.

Software and system development

As with other recent safety technologies from Volvo Cars, the multi-adaptive safety belt is designed to receive updates remotely. These updates may include refinements based on newly collected data or improved response strategies. Furthermore, the belt system operates as part of a larger safety structure that includes airbag deployment, occupant detection systems, and driver assistance features. This coordination exists to make the driving experience safer, as the different safety systems can respond in alignment.

The development and testing of the new safety belt took place at the Volvo Cars Safety Centre, which marks its 25th year of operation. The facility supports full-scale crash testing and controlled reconstructions and plays a role in developing technologies that are tested beyond official safety requirements.

“The world’s first multi-adaptive safety belt is another milestone for automotive safety and a great example of how we leverage real-time data with the ambition to help save millions more lives.”

Åsa Haglund, head of Volvo Cars Safety Centre