Header: Lotte Scheder-Bieschin & Andrei Jipa

Researchers at ETH Zurich’s Block Research Group have developed a new way to build floors that could drastically cut down on construction waste. Called Unfold Form, the system is a lightweight, reusable mold for making vaulted concrete floors. Led by Lotte Scheder-Bieschin, along with Mark Hellrich, Tom Van Mele, and Philippe Block, the project is a fresh take on material-efficient construction. It’s already getting noticed, helping Scheder-Bieschin win the Emerging Architect of the Year prize at the recent BLT Built Design Awards.

Strength from shape, not stuff

Flat concrete floors are standard, but they are incredibly wasteful. They need a lot of concrete and steel reinforcement bars to hold themselves up over a span. Unfold Form borrows an old idea from Gothic cathedrals: strength through geometry.

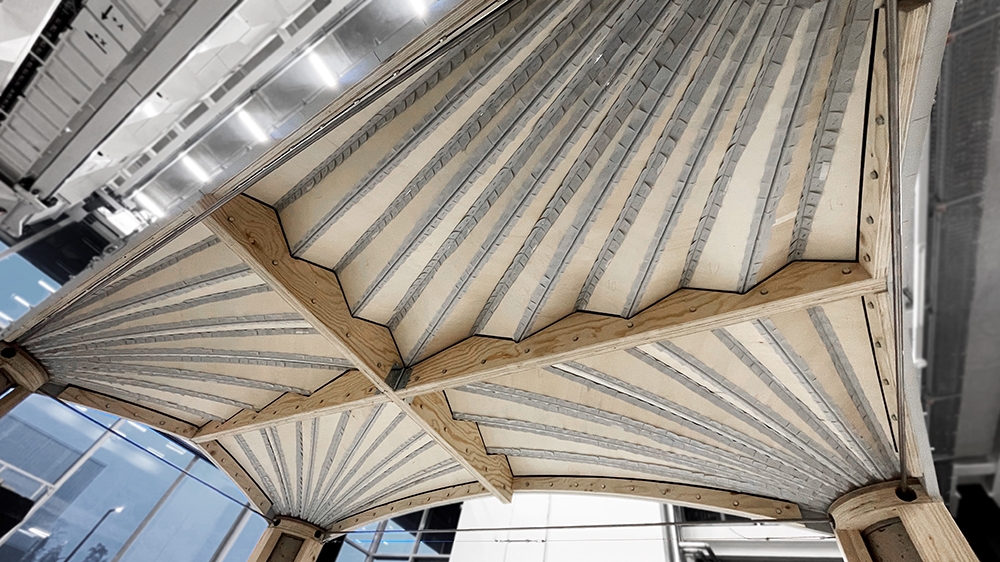

Instead of a thick, flat slab, the system creates a thin, vaulted concrete shell. This shell gets its power from its specific curved shape, letting it carry loads mostly in compression, which concrete is great at. The results are big: this method cuts concrete use by 60% and steel reinforcement by 90% compared to a typical floor slab. The shape isn’t just for looks; it’s the core of the floor’s efficiency.

How it works: Plywood, textiles, and curved creases

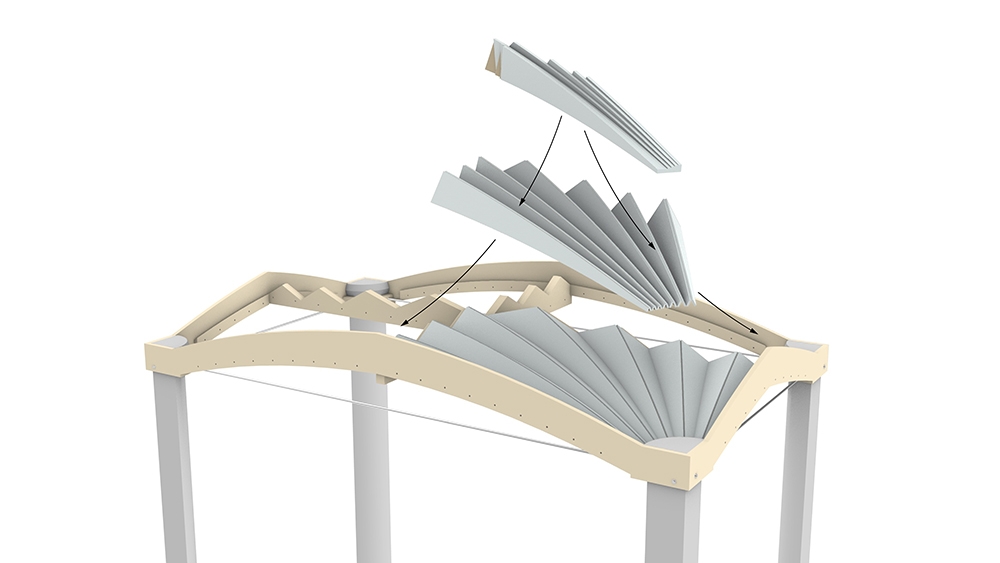

The real magic of Unfold Form is the formwork; the mold used to pour the concrete. It’s not a heavy, custom-built box. Instead, it’s made of bending-active plywood plates connected by flexible textile hinges.

This isn’t just regular folding. The team developed a new method called “curved-crease unfolding.” The formwork is flat-packed for easy shipping. On-site, it simply unfolds like a fan into a rigid, three-dimensional, corrugated shape. These waves, or corrugations, are key. They make the thin plywood mold stiff enough to stand on its own and support wet concrete, and they also create ribs in the final concrete floor, adding even more structural strength.

High-tech design, low-tech fabrication

While the shape was figured out using advanced computational design tools, building it is surprisingly cheap and straightforward. The system uses basic 8mm-thick plywood and a PVC-coated polyester textile. The total material cost for the prototype was only around 650 CHF.

This “high-tech design, low-tech fabrication” approach means it can be used almost anywhere. It doesn’t need a fancy factory or highly skilled labor to be put together. The entire formwork for a room-sized floor can be assembled in just 30 minutes. The plywood mold itself weighs only 24 kilograms but can support 1,000 kilograms of concrete.

From Zurich to Cape Town

To prove it works, the team built half-scale prototypes in Zurich, Switzerland, and Cape Town, South Africa. The flat-packed formwork was so compact (measuring 160 x 40 x 25 cm), that it was transported from Switzerland to South Africa as checked luggage on an airplane.

Once deployed, this tiny 24kg package unfolded to create a mold for a concrete shell spanning 3 meters by 1.8 meters. The formwork proved to be reusable, working for multiple concrete pours without losing its quality. The resulting wavy ceiling is a direct, honest expression of how it was made and how it stands up. The team is now looking to use this system with new bio-concretes to build sustainable, low-cost housing.

Project info

University: ETH Zurich, Block Research Group

Lead Designer: Lotte Scheder-Bieschin

Design Team: Lotte Scheder-Bieschin, Mark Hellrich, Tom Van Mele, Philippe Block

Photo Credit: Lotte Scheder-Bieschin & Andrei Jipa

Project Location: Zurich, Switzerland

Project Date: 15.02.2024