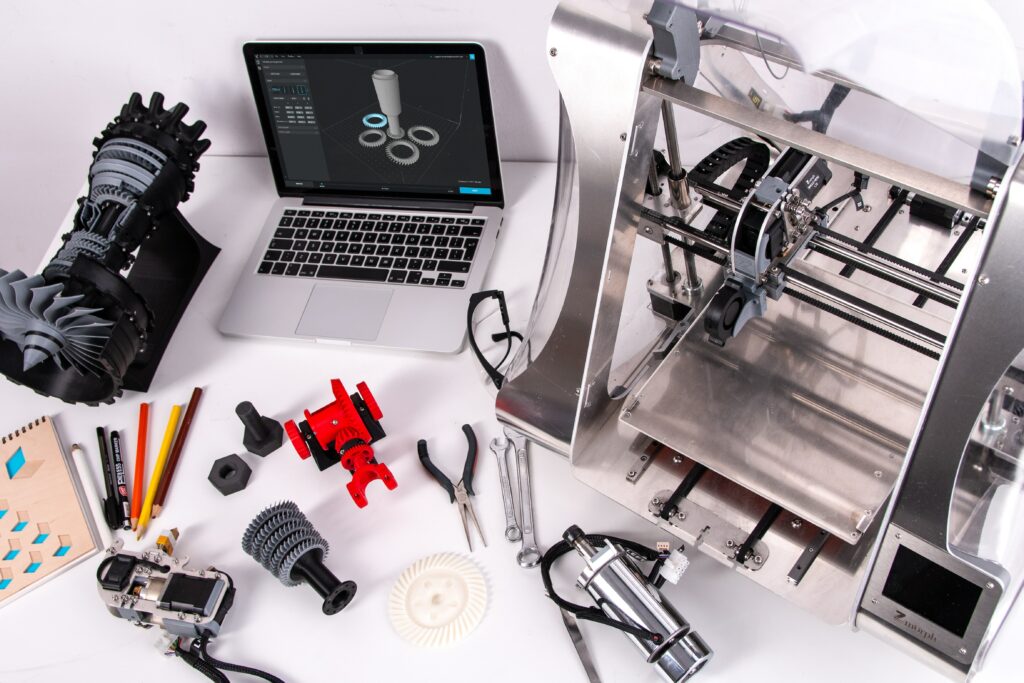

The fact that one person can single-handedly develop a product now is largely thanks to 3D printing. In the ever-changing landscape of innovation and entrepreneurship, there are those who not only adapt to the challenges they face but redefine entire industries with their ingenuity.

The birth of Keystone Outdoor Gear Co

Amidst the global pandemic, Alex Sinton, a visionary with a passion for outdoor adventure, found himself at a crossroads. Determined to seize control of his destiny, he founded Keystone Outdoor Gear Co (KOGC) during these challenging times. “I’ve always wanted to create products, ever since I was a little kid. And when Covid-19 hit I became part of the mass layoffs. Then I realized that it was time to try to do my own thing. And through my list of ideas, I figured that this table was doable,” explains Sinton.

TakTable™ is a portable field table that has taken advantage of new technologies. y incorporating 3D printing for plastic part production instead of injection molding for their portfolio of TakTable™ accessories, they have quickly expanded their product line to include designs reactive to their user base.

The Philosophy of Quality and Cost

Sinton’s philosophy at KOGC was clear: prioritize quality and cost and deemphasize the importance of time. In his own words, “Quality and cost were the important factors, while time was not. And I think that was great because it gives you the time to think about what you want.” This philosophy laid the foundation for KOGC’s innovative journey.

The role of 3D printing

Central to KOGC’s success was their embrace of 3D printing technology, a groundbreaking decision. Traditional mass manufacturing of plastic parts requires the use of precision steel tools mounted in large presses. 3D printing on the contrary allows for quick design-test-build cycles to arrive at a finished product in a brief period of time. Afterward, limited production runs can be produced in a matter of hours or days, practically on-demand, leading to agile inventory control.

This innovative approach brought several advantages, with Sinton elaborating, “3D printing allows us to create parts layer by layer, similar to CNC machining but adding material instead of removing it.”

He further explains how this transformed their production process. “It allows for quick design-test-build cycles to arrive at a finished product in a brief period of time. Afterward, limited production runs can be produced in a matter of hours or days, practically on-demand, leading to agile inventory control.”

“Without 3D printing, I could not have gone through the hundreds of prototype parts it took to test and refine the designs and had the confidence in them to go to tooling,” adds Sinton.

Rapid Design Iterations

3D printing facilitated swift design iterations, enabling Sinton to identify and rectify design flaws quickly. This agility in the design process sets KOGC apart in the outdoor gear industry. It allowed them to “arrive at a final design for their flagship product, the TakTable™,” Sinton reveals, “within about a year or so.”

Lowering Investment Barriers

Unlike traditional manufacturing, 3D printing eliminated the need for expensive precision tools, making it accessible to a small company like KOGC. This reduced the upfront investment cost and encouraged experimentation. “Without 3D printing, many of these products, most of which were suggested by our users, would not exist at all,” says Sinton.

However, he acknowledges that this flexibility had trade-offs. “Additive manufactured parts may take several hours for a single part to be completed, versus seconds to minutes with injection molding. Material costs are higher too. A printer uses filament sold in spools for $15 or more per kilo, while injection molding plastic is sold in bulk for dollars a kilo. For larger production runs, like the TakTable itself, 3D printing is cost-prohibitive. But by adding flexibility to their main product, it was possible to use 3D printing for add-ons.”

Challenges

However, KOGC faced its share of challenges in an industry dominated by monolithic players. The outdoor gear market had long been held hostage by established giants. To stand out and gain awareness, KOGC had to do more than just innovate. They had to make their products not only innovative but also more accessible and cost-effective for their customers.

Rewards

The most rewarding thing according to Sinton is the positive change you could bring to people’s lives with your designs. “It is great to see people having a better life because of the effort you have put into your product,” elaborates Sinton. Moreover, he explains that with time it becomes less about the money and sales and more about himself. “I did this because I wanted to solve a problem I was facing daily.”