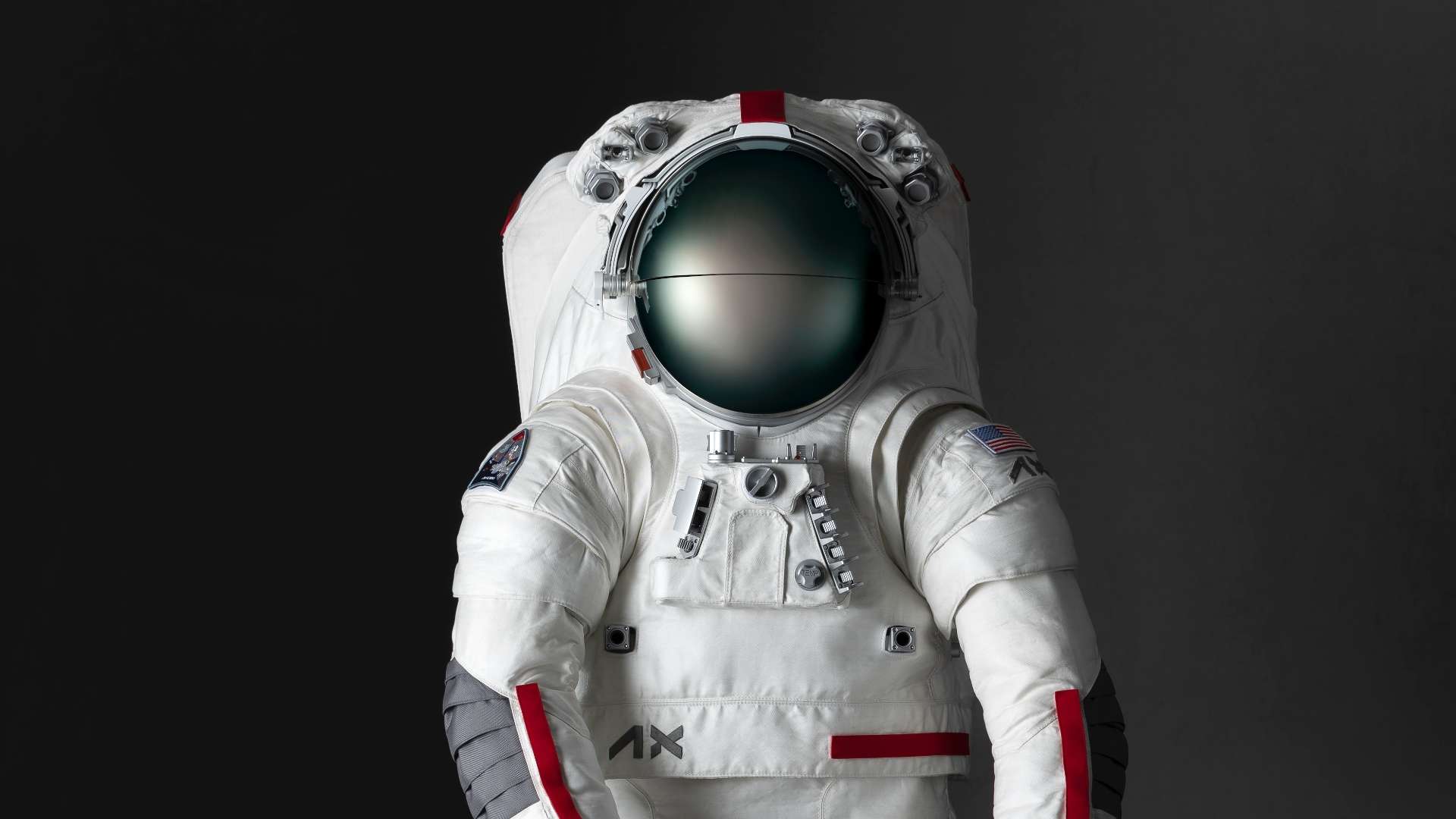

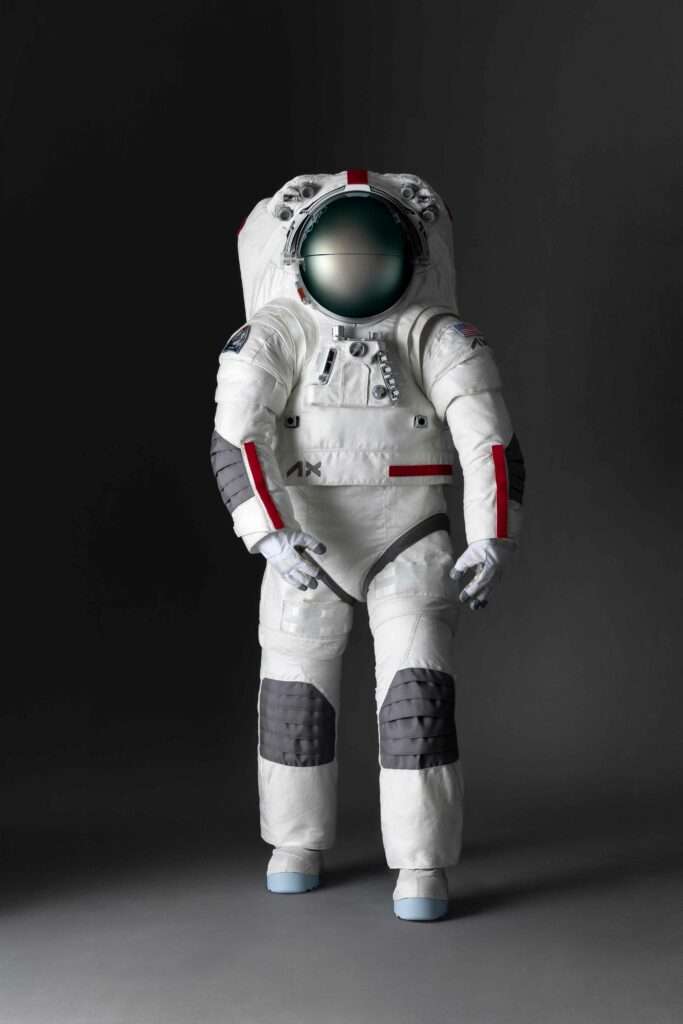

Header: Courtesy of Axiom Space

At the most recent International Astronautical Congress in Milan, Italy, Axiom Space and Prada revealed the flight design of the Axiom Extravehicular Mobility Unit (AxEMU) spacesuit that will be used for NASA’s Artemis III mission. The two industry leaders jointly developed the outer-layer design and materials, marking an age where engineering meets aesthetics and astronauts can show a bit of human style to the void—who knows what could be watching them?

“Our elite teams have redefined spacesuit development, establishing new pathways to innovative solutions and applying a state-of-the-art design approach for the AxEMU,” said Matt Ondler, Axiom Space President. “We have broken the mold. The Axiom Space-Prada partnership has set a new foundational model for cross-industry collaboration, further expanding what’s possible in commercial space.”

During development, Axiom Space displayed the spacesuit with a dark cover layer to conceal the new technology. However, the finished product worn on the lunar surface will be made from a white material that protects astronauts from high temperatures and lunar dust.

Lorenzo Bertelli, Prada Group Chief Marketing Officer and Head of Corporate Social Responsibility, said, “Going beyond our limits is one of the company’s values that reflects the spirit of the Prada brand and my parents’ vision. I’m proud of the result we’re showing today, which is the first step in a long-term collaboration with Axiom Space. We’ve shared our expertise on high-performance materials, features, and sewing techniques, and we learnt a lot. I’m sure we’ll continue to explore new challenges, broaden our horizons, and build new scenarios together.”

Prada’s knowledge and experience of materials and production processes were crucial in developing the spacesuit’s outer layer. Prada’s design and product development teams worked alongside Axiom Space engineers on customized material recommendations that would protect astronauts against the unique challenges of the lunar environment, sharing their knowledge and inspiring millions of people around the world.

Prada’s expertise, technologies, and sewing methods made the outer layer comfortable and functional, which is incredible when one remembers that before, these materials only had the task of protection. By bringing a new vision to the table, Prada managed to do what most designers strive their whole lives to achieve: find how a particular element can gain more functionalities.

Since being awarded its first Artemis task order in 2022, valued at $228 million, Axiom Space has capitalized on the public-private agreement with NASA, seeking out experts in diverse industries to aid in developing and designing this next-generation spacesuit. This search is part of their AxEMU program, which believes that partnerships can enhance our space exploration capabilities.

“We are pioneering a new era in space exploration where partnerships are imperative to the commercialization of space,” said Russell Ralston, Executive Vice President of Extravehicular Activity at Axiom Space. “Partnerships build a strong, cohesive team, enabling industry experts to provide cutting-edge technology, specialized products, and services to drive innovation. For the first time, we are leveraging expertise in other industries to craft a better solution for space.”

The spacesuit is called “NASA’s Exploration Extravehicular Mobility Unit“, or simply “AxEMU“, and it was designed to provide flexibility, performance, and safety, as well as specialised tools to aid in exploring the lunar south pole. The suit can accommodate various body types, including females and males, from the first to the 99th percentile (anthropometric sizing). Due to the materials used, the AxEMU can withstand extreme temperatures at the lunar south pole and endure the coldest temperatures in the permanently shadowed regions for at least two hours. The result is impressive: astronauts can perform spacewalks for at least eight hours.

The AxEMU is comprised of multiple redundant systems and an onboard diagnostic system to ensure safety for crewmembers, a regenerable carbon dioxide scrubbing system and a cooling technology to remove heat from the system, coatings on the helmet and visor to enhance the astronauts’ view of their surroundings, as well as custom gloves made in-house more advanced than the ones used today. Furthermore, the spacesuit’s architecture includes life support systems, pressure garments, avionics, and other systems to meet exploration needs and expand scientific opportunities. Axiom Space developed the AxEMU using a single, foundational architecture that is evolvable, scalable, and adaptable for missions on the lunar surface and in low-Earth orbit (LEO).

Axiom Space has been working on this next-gen spacesuit over the past two years to support the Artemis III mission, applying countless tests and simulations with astronauts and engineers at Axiom Space, SpaceX, and NASA facilities. To ensure the suit could withstand the lunar environment, testing was conducted underwater with an unoccupied spacesuit at NASA’s Neutral Buoyancy Laboratory (NBL) and in reduced gravity simulations at NASA’s Johnson Space Center.

After all this work and time, the AxEMU suit is in the final development stage. It just completed a pressurised simulation with Artemis III partners, the first test of its kind since the Apollo era. The spacesuit will continue to undergo testing and will enter the critical design review phase in 2025.